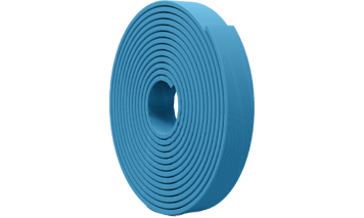

KKB Guiding Tape: A Composite Solution for Demanding Hydraulic Applications

Reliability, durability and precision are the key determinants of performance in hydraulic systems. In these systems, guiding elements are among the components that directly affect the accuracy of movement and equipment life. Kastaş Sealing Technologies, responding to this critical need, offers a new generation composite solution with its KKB Guiding Tape, designed to meet the demands of modern hydraulic systems.

Reliability, durability and precision are the key determinants of performance in hydraulic systems. In these systems, guiding elements are among the components that directly affect the accuracy of movement and equipment life. Kastaş Sealing Technologies, responding to this critical need, offers a new generation composite solution with its KKB Guiding Tape, designed to meet the demands of modern hydraulic systems.

KKB is a leading solution in the following applications:

• Mobile hydraulic systems

• Construction and industrial machinery

• Agricultural equipment

• Press systems

• Cranes and lifting equipment

Advanced Composite Structure

KKB Guiding Tape is manufactured from a high-performance composite material consisting of synthetic fibre and specially formulated polyester resin. Developed with controlled production parameters, this structure provides low wear ratio and high mechanical strength.

These features offer a reliable and long-lasting solution for guiding elements operating under dynamic loads and radial forces.

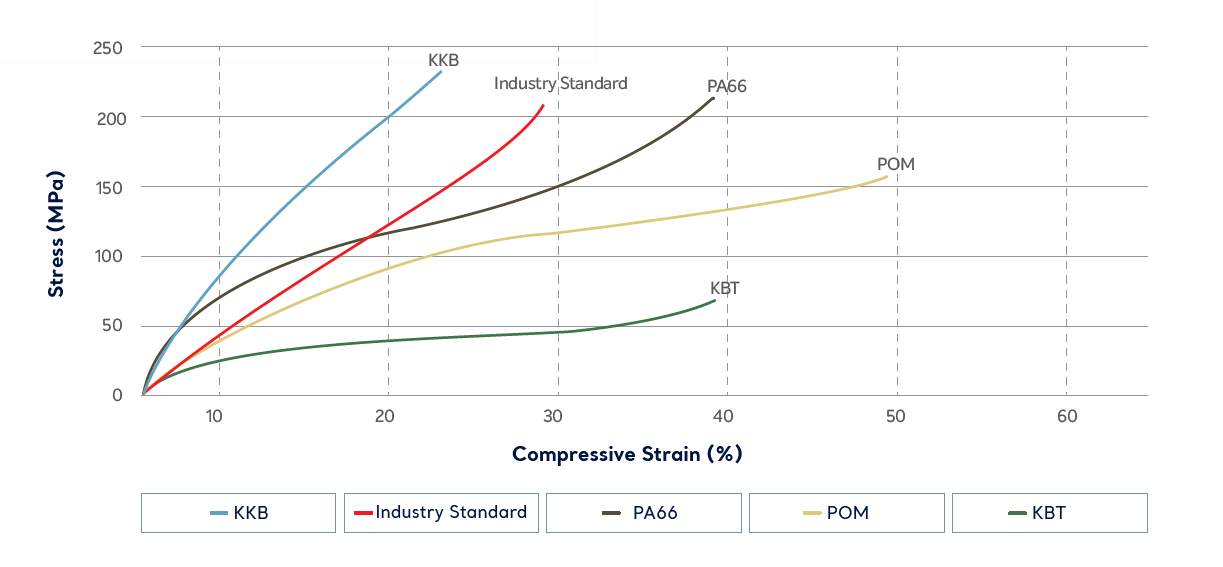

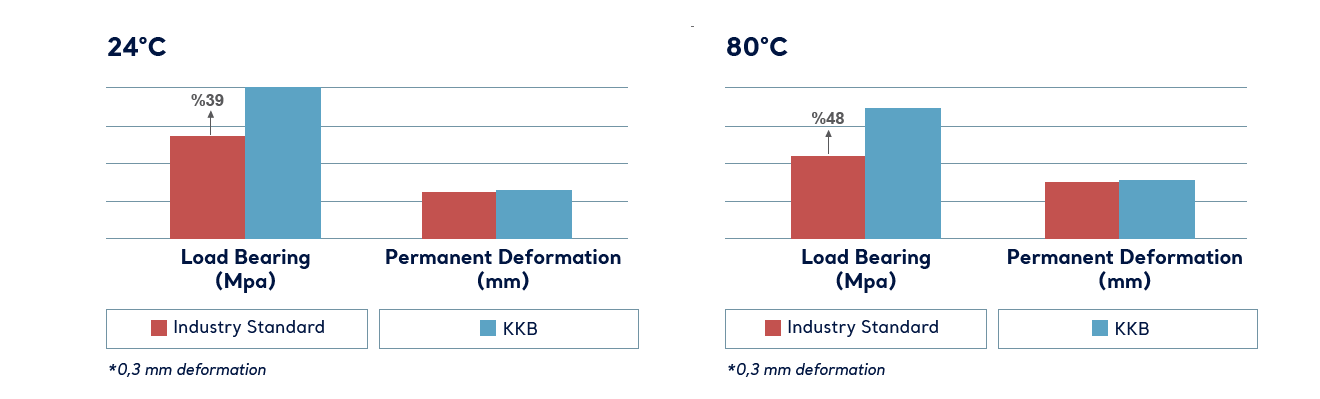

Compared to traditional materials, KKB:

• has a load-bearing capacity above industry standards,

• lower permanent deformation,

• and stable performance at temperatures up to 80°C.

These features make KKB ideal for systems requiring high tolerance accuracy, low maintenance requirements and a long service life.

Low Friction, High Durability

Thanks to its special composite structure, KKB reduces energy losses with a low friction coefficient and minimises surface damage or stick-slip effects.

High load-carrying capacity and low deformation capability ensure stable guidance of the piston or rod, significantly reducing wear on system components.

KKB is manufactured with tight tolerances, ensuring a perfect fit in the channel.

In addition to standard dimensions, custom cutting options allow KKB to be easily integrated into both standard and application-specific dimensions.

This precision engineering approach enhances system reliability and performance consistency.

Efficiency and Sustainability

KKB's low friction characteristics contribute to energy efficiency throughout the system; it reduces heat generation and extends the life of system components.

This results in less maintenance, longer operating time and lower total cost of ownership. These advantages of KKB directly align with energy saving and environmental sustainability goals.

17631297481575IMRxr.jpg)

17631297481575IMRxr.jpg)