ISO 9001:2015

QUALITY MANAGEMENT SYSTEM

Kastaş has retained its leading position in the sector due to the high quality of our products and services, which has led to continued customer satisfaction.

Every link of the production chain at Kastaş, starting from the raw material to the final product,

is guided by the"Zero Defects" objective.

Kastaş Quality System is based on all applicable international standards and is an important part of our organizational culture. Apart from adhering to the ISO 9001 and IATF 16949 standards, which are audited by international institutions, we also employ comprehensive internal audit processes to ensure the effectiveness of our quality system in all our business processes. In accordance with continuous improvement studies, along with Lean Manufacturing and Kaizen practices, we are continually upgrading our quality system in line with our business goals.

QUALITY POLICY

Kastaş carefully analyses the needs and expectations of its customers, suppliers and employees, and continuously improves all its business processes in line with an innovative approach.

It is determinedly moving forward towards its vision of becoming the world's preferred manufacturer of sealing technologies.

In this context, Kastaş is committed to:

Creating a working environment that promotes personal responsibility and teamwork,

as well as the adherence to the quality management system requirements by all employees,

and where solutions are produced responsibly

Ensuring the continuity of customer satisfaction through total quality management

Developing innovative solutions by forecasting the future needs of the sector

Collaborating with the key suppliers to ensure the attainment of competencies needed for achieving common goals

Increasing the efficiency of all units via continuous development

Carrying out all organizational activities in a socially and environmentally responsible manner,

and in accordance with the company values and principles Aligning the company quality policy with the requirements of quality management standards and world standards.

QUALITY ASSURANCE AND QUALITY CONTROL

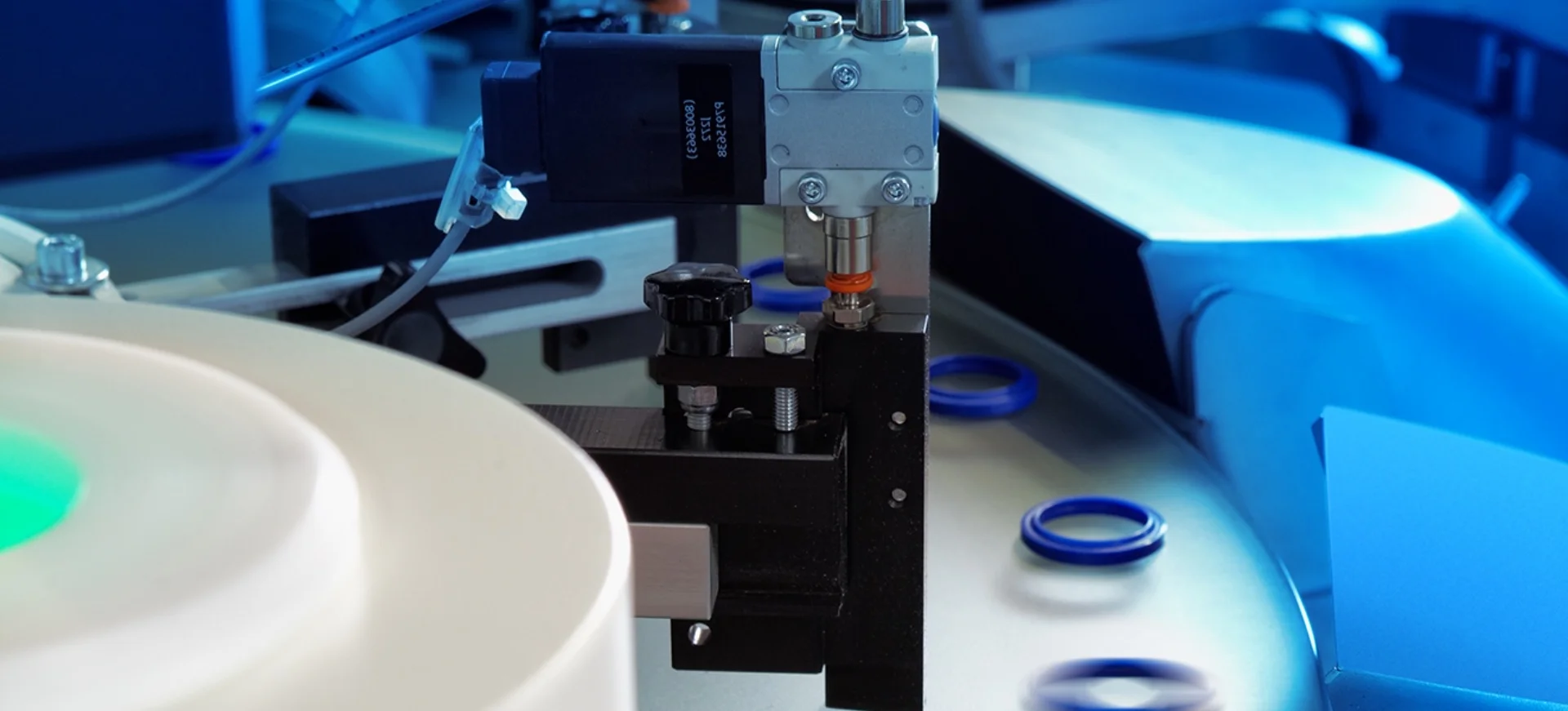

All processes affecting product quality at Kastaş are carried out with advanced technology and modern equipment, as our quality assurance system spans from product design to raw material supply, and extends to all production processes, including mold production.

R&D TEST CENTER

During the design and development stages, all standard and special products are tested for lifecycle performance at our R&D Test Center.

QUALITY LABORATORY

From thermoplastics supplied by our global suppliers to elastomers developed and produced by Kastaş, all raw materials are tested on a lot basis in our quality laboratory equipped with modern equipment. Moreover, initial sampling approvals and product measurements are carried out with advanced measuring devices.

AUTOMATIC VISUAL AND DIMENSIONAL INSPECTION

Millions of sealing elements produced at Kastaş every year undergo 100% visual inspection. Majority of these products are controlled with high precision in high-capacity automatic visual and dimensional inspection devices.

Engineering for motion