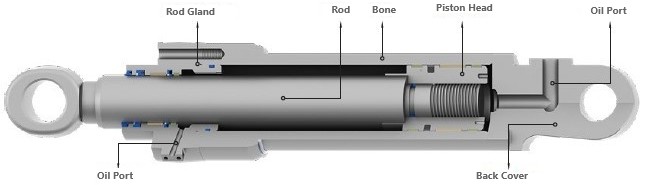

What is Hydraulic Cylinder?

Hydraulic cylinder is a circuit element that converts hydraulic energy into mechanical energy and is used to obtain linear motion. The hydraulic energy generated by the pump is converted into linear or angular motion with the help of a cylinder. Cylinders can be made in various structures, diameter and stroke depending on the purpose of use. These are machine elements that are generally used in systems requiring excessive forces and have a velocity below 0.5 m / s.

Cylinder Types According to Functions

According to their functions, cylinder types can be evaluated in 3 main groups as single acting, double acting and telescopic cylinders.

Single Acting Cylinders: It is the type of cylinder in which hydraulic fluid enters the cylinder from a port. While the piston head is moved in one direction by the fluid, the return takes place by means of a mechanical spring or weight. Single-acting sealing elements should be selected for this type of cylinder.

Ex: Power Cylinders, Freight elevators

Single Acting – Provides Sealing with the help

of Rod Sealing Elements

Single Acting – Provides Sealing with the help

of Piston Sealing Elements

Telescopic Cylinders: Type of cylinders are use to obtain high strokes. They consist of many interlocking cylinders of different diameters. As the cylinders go out, the rod stages are opened sequentially; while closing, the rod stages join each other. It is possible to obtain more strokes than a hydraulic cylinder that takes up less space. Generally single acting telescobic cylinders are used in mobile systems.

Ex: Crane cylinders, tipper cylinders

Single Acting Telescopic Cylinder

Double Acting Telescopic Cylinder

Double Acting Cylinders: It is the type of cylinder where the fluid affects on the piston head from both directions. Movement of the cylinder provided by fluid in both directions. This type of cylinders can do work both going forward and backward and they are generally most widely used type cylinders. Piston seals should be chosen from double acting seal designs.

Ex: Construction machinery cylinders, agricultural cylinders

Double Acting Cylinder

| APPLICATION PARAMETER |

Light Duty |

Medium Duty |

Heavy Duty |

| Pressure Range | < 100 bar | < 250 bar | > 250 bar |

| Pressure Spikes | None or Low | Not to exceed twice the system pressure. |

Pressure spikes that may be several times the system pressure and o a longer duration. |

| Temperature Range | -20/+70 ˚C | -30/+100 ˚C | -40/+110 ˚C |

| Contamination | None or Low | Operate in medium contamination environments |

Operate in high contamination environments |

| Side Loading | • Short stroke cylinders • No axial load or light duty cylinders |

• Operate vertically • Medium axial load |

• Long stroke cylinders • Excessive axial load • Operate both vertically and horizontal |